Blog

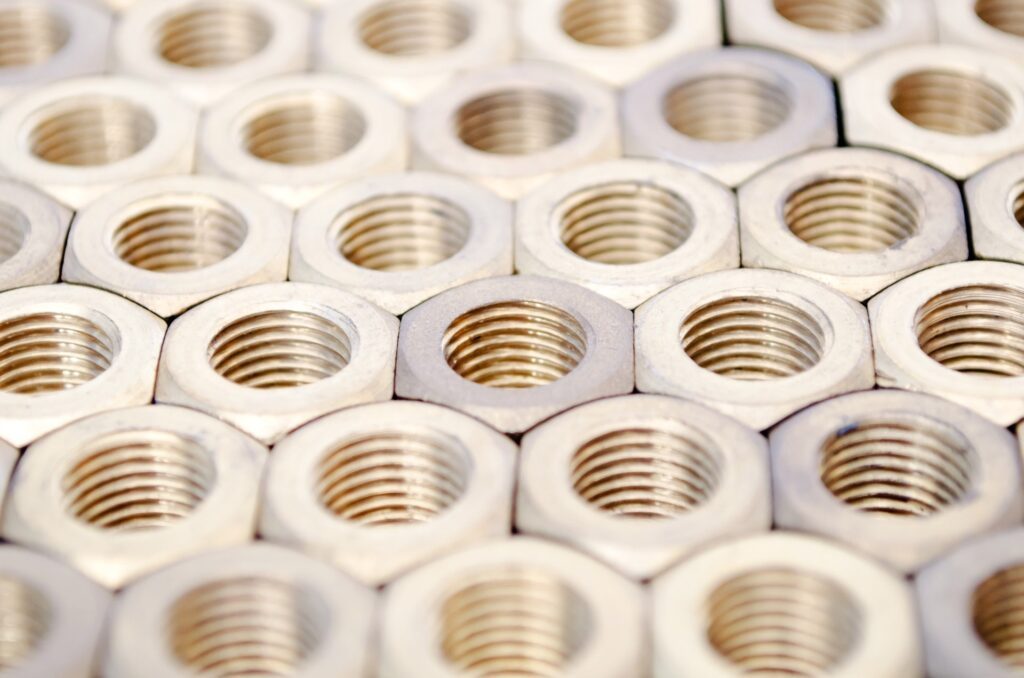

An Overview of Fasteners: Bolts, Nuts, and Washers

Bolts, nuts, and washers may be small and often overlooked, but their role in construction and manufacturing is immense.

The unacknowledged heroes of the industrial and construction industries are fasteners. They are the fundamental elements that bind everything together, from the cars we drive to the buildings we work in. Among these, bolts, nuts, and washers form a trinity of connectivity, each playing a critical role in ensuring the integrity and safety of joined components. This article provides a comprehensive overview of these fundamental fasteners, exploring their types, uses, and the intricacies of their selection and application.

Bolts: The Threaded Anchors

A threaded fastener with an exterior male thread is called a bolt. Screws are externally threaded fasteners that are closely linked to bolts, but the two differ in their intended use. Bolts are typically used to assemble two unthreaded components, with the aid of a nut.

Types of Bolts

There are numerous types of bolts, each designed for specific applications and loads. Let’s look closely at each type

Hex bolts: Characterized by a hexagonal head, these are among the most common types of bolts and are used in a variety of applications.

Carriage Bolts: These have a smooth, domed head that pulls into the material to prevent spinning during installation, with a square area underneath.

Anchor Bolts: As the name suggests, these are used to anchor structural elements to concrete.

U-Bolts: Shaped like the letter ‘U’, these bolts are used to support pipework or to attach cables.

Each bolt type comes in different sizes and materials, including steel, stainless steel, brass, and more exotic alloys for specific environmental conditions.

Nuts: The Mating Counterparts

Nuts are the female counterparts to bolts and are internally threaded to match the bolt’s external threads. They provide the clamping force to secure the bolt in place.

Types of Nuts

Just as with bolts, there are many types of nuts, such as:

Hex Nuts: The most common type that pairs with hex bolts for general-purpose fastening.

Lock Nuts: These have a feature such as a nylon insert or distorted thread that resists loosening under vibrations and torque.

Wing Nuts: Designed to be tightened and loosened by hand thanks to their ‘winged’ design.

Flange Nuts: These have a wide flange at one end. This serves as a built-in, non-spinning washer.

Washers: The Pressure Distributors

Washers are little plates having a hole in them that are usually used to disperse the load of a bolt or nut or other threaded fastener. They also prevent damage to the surface being fastened and can help to prevent loosening due to vibration.

Types of Washers

The variety of washers include:

Flat Washers: The most common type, which evenly distributes the load and prevents damage to the surface.

Spring Washers: Used to prevent fastening or loosening due to vibrations.

Lock Washers: Designed to secure fasteners that may rotate or lose friction.

Fender Washers: When a greater bearing surface is required, these are utilised because of their larger outside diameter.

Material and Grade Considerations

The material and grade of bolts, nuts, and washers are chosen based on the application. For example, stainless steel is used for its resistance to corrosion and is ideal for use in environments exposed to water or chemicals. The grade of a bolt indicates its strength, with higher grades being stronger. It’s crucial to match the grade of the nut with the grade of the bolt for optimal strength and safety.

Understanding Threads

The thread is the spiral structure on the bolt or screw that allows it to mate with a nut or other internally threaded component. Thread dimensions are standardized so that fastening components are compatible with each other. Because mismatched threads might cause the joint to fail, the thread pitch, or the space between the threads, is very important in the selection process.

Selection and Application

The selection of the appropriate bolt, nut, and washer is crucial. Factors to consider include the materials being fastened, the type of forces involved (shear, tension, etc.), environmental conditions, and whether the joint will be subjected to vibration or movement. For high-stress applications, such as in structural or mechanical engineering, precise calculations are made to determine the correct size and grade of fasteners to be used.

Installation and Tightening

Proper installation is as important as selecting the right fastener. Bolts should be tightened to the manufacturer’s specified torque to ensure the joint is secure but not over-tightened, which can lead to bolt failure. Techniques such as using a torque wrench or tension control bolts are employed to achieve the correct level of tightness.

Maintenance and Inspection

To guarantee the lifetime and security of attached joints, routine upkeep and inspection are essential. This includes checking for signs of corrosion, ensuring nuts are still tight, and replacing any fasteners that show signs of wear or damage.

Conclusion

Understanding the differences, applications, and nuances of these fasteners is key to ensuring the integrity of countless structures and machines. Whether you are an engineer, a DIY enthusiast, or simply someone curious about the nuts and bolts of fasteners, appreciating these components can give you a new perspective on the built world around you.

The correct selection, application, and maintenance of these fasteners are paramount for the safety and longevity of any project. As technology and materials advance, the world of fasteners will continue to evolve, yet the fundamental principles of these essential components will remain the cornerstone of assembly and construction.

More reading

9 Tips for Organizing a Workshop: Tool Storage Solutions